As we all know, due to the improvement of PET film, many PET film manufacturers will position themselves as manufacturers of high-end products, but high-end product manufacturers can not brag, which also needs to privately ensure that the quality of their products is accepted by high-end product manufacturers, then you need PET film manufacturers to be strict with themselves, in accordance with the requirements and specifications to constrain themselves. To enable themselves to achieve greater breakthroughs in products. Therefore, in the production process of PET film, not only requires a strict production environment, but also requires strict testing standards, so how do PET film manufacturers test it?

First of all, they measured the tensile peel strength of the left and right sides of a film (a roll) to meet the customer's adhesive force requirements, and then visually observed whether the PET film had any abnormal conditions such as coating leakage and white spots, and tested whether the PET film degumming again. The whole detection process was very strict. If there is a little negligence, it may lead to damage or pollution of customer products, so PET film manufacturers will spend some manpower and material resources on product testing to ensure the quality of each product.

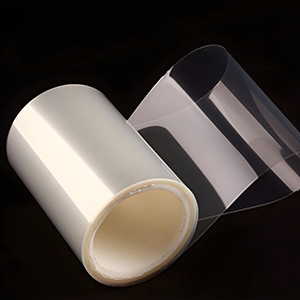

AoChuan Shun New Materials is a manufacturer with 20 years of experience in the production of protective film. They have a good production environment of a thousand-grade clean workshop, and they will strictly control the quality of each protective film during production or before shipment. We hope to communicate with your company about the relevant technical requirements of PET film.