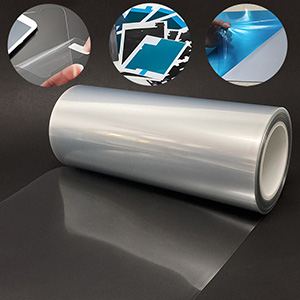

In life, many manufacturers use silicone PET protective film at the same time, bubbles will appear in the use process, affecting the quality of use. But how to prevent bubbles during use? For the hard point protective film, the bubble will be visible before the protective film has not been combined. Therefore, the use of PET mesh protective film, can effectively prevent the generation of bubbles, PET mesh protective film has a regular distribution of small dots, after the backlog of gas will be discharged through the various holes, so the product is widely used in die-cutting and other industries. The following will introduce several problems that will occur in PET mesh protective film:

First, the degumming problem of silicone PET mesh protective film

Degumming generally appears on the profile protective film is more, the user will be installed after the profile will be separated from the protective film, protective film after separation with its own adhesive does not follow the protective film falls off together, but stays on the surface of the profile.

Solution: Use a clean cloth stained with a little alcohol, repeatedly wipe the degummed surface, but the force should not be too large during the wiping process to prevent damage to the protected surface.

Second, the product is not firmly pasted

The main reason for the poor adhesion is that the adhesive degree does not match the adhesive surface, and a protective film with higher viscosity can be used to increase the gram of the glue to increase the viscosity of the protective film. It may also be that the surface to be pasted is not clean, there are pollutants and other phenomena, affecting the paste effect.

Solution: Increase the glue gram (glue amount) to ensure that the surface is clean.

Three, in the use of the two ends of the warp

The main reason for the warping of both ends of the protective film is that the tensile degree of the protective film is too large in the production process, and the shrinkage phenomenon occurs during the use of temperature changes.

Solution: Adjust the tensile strength during use, and pay attention to the influence of temperature on PET mesh protective film during use.