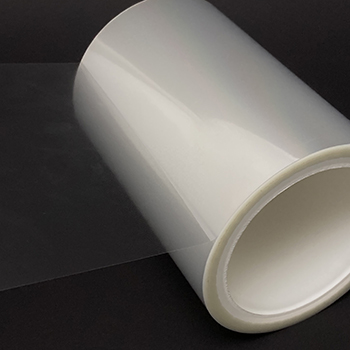

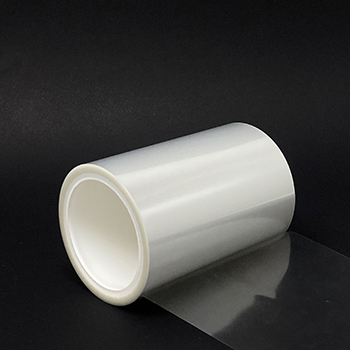

As we all know, incoming material testing is an indispensable environment for every manufacturer. In order to ensure that there will be no goods with quality problems in the batch of goods supplied by the supplier, the factory must arrange personnel to conduct incoming material testing and registration of the goods, such as PET silicone protective film, which should be registered immediately after unloading. Record the quantity of goods, measure the thickness of the protective film with a dial indicator, observe the appearance of the protective film with the naked eye, including whether there are black spots, whether the color is normal and other quality problems of the PET silicone protective film, and then record the storage.

Because as a manufacturer, we need to check the quality of each environment of the PET silicone protective film to avoid finding that the original film has certain quality problems during the production process, which will not only affect the time cost, but also affect many other places, and also cause a certain degree of loss to the company. Therefore, PET silicone protective film companies should treat incoming material detection as an important thing.